NON DESTRUCTIVE TESTING (NDT)

Geotest perform Non-Destructive testing (NDT) in connection with a special inspection of existing concrete structures, repair projects or quality control of new projects.

The NDT methods can give a detailed knowledge of the current state of a structure without causing damages in the structure and they should be combined with invasive tests to calibrate the results.

The staff of GEOTEST is properly trained in planning test programs, in using the test systems and interpreting test results.

Testing for voids in grouted cable ducts of bridges decks

We perform Ultrasound 3D tomography measurements in order to locate suspicious areas (voided) around and inside the duct of the bridge. Also, by ultrasound measurements (B-scans), the shear velocities of concrete are estimated

Following the tomography evaluation, at certain suspicious testing positions, Impact-echo tests (ASTM C1383) are perform in order to estimate the depth and the extent of possible voids around or/and into the duct.

Finally, micro-drills and/or core drilling are execute at the most suspicious testing points in order to evaluate the condition of the ducts. Then, opening of the corrugated metallic ducts is perform by using special tools and injection grout sampling taken to examination to chloride concentration.

Also, by visual observation we perform condition evaluation and the Corrosion class of the strands.

Localization tendons duct of prestressing bridge

We use Ground Penetration Radar (GPR) technology in order to determine the number and geometry of the prestressing tendons.

Our equipment has the ability to detect tendons up to a depth of 40cm using 2d and 3d scanning.

Furthermore using the appropriate software we can perform further analysis in the office or in the laptop.

Evaluation of Deck Waterproofing Integrity using the Impulse – Response method (ASTM C1740)

We perform testing in bridges decks using the Impulse – Response method (ASTM C1740) to evaluate the waterproofing integrity and the condition of the concrete of the top of the deck,.

The Impulse – Response method is a comparative, non Destructive Testing method that has the ability to map big areas in a short time.

The results of this method is calibrated with cores on test positions that present different response according to the average mobility plot.

Investigation of failures on concrete floors and repair suggestions

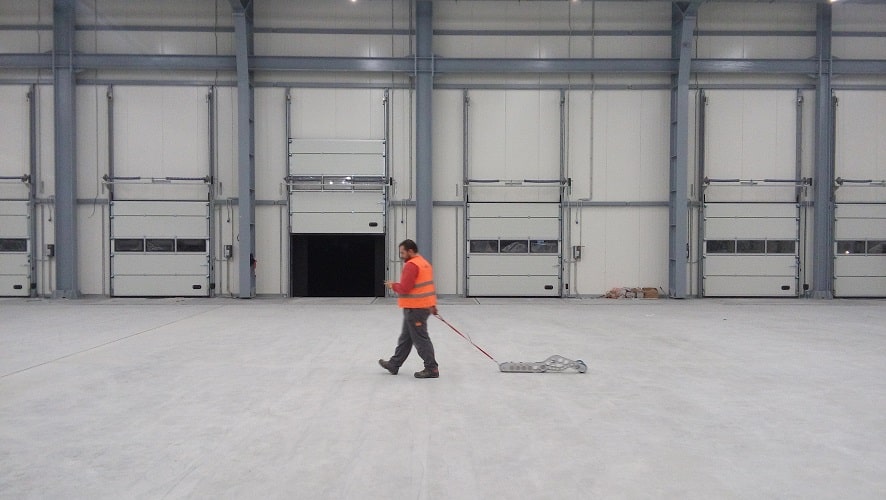

Flatness measerement of concrete floors (DIN 18202)

We can survey the floor’s flatness with the DINmeter equipment which tests the floor against the limits of DIN 18202 specification. The DINmeter produces a continuous differential profile of the floor at the center point from a mean line generated by two points 1 metre apart. Precision is guaranteed by the sub-millimetre accuracy with laser-based sensors.

Corrosion evaluation – Service life of the structure

![IMG_0352 [1024×768]-min](https://geotest.gr/wp-content/uploads/2020/05/IMG_0352-1024x768-min.jpg)

Evaluation of condition in concrete structure after fire

Measurement of bond strength by pull off

Measuring the tensile bond strength of concrete (EN 1504 – ASTM C1583). Evaluate the in-place bond strength between a repair overlay and applied materials to the substrate Evaluate the effect of surface preparation procedures on the tensile strength of the substrate before applying a repair material or overlay

Adhesion strength of marking strips (EN 1542)

Adhesion strength of tiles

Pile Integrity Testing

We perform quality assurance of piles in deep foundation according to Cross hole sonic logging (ASTM D 6760 and AFNOR NF P 94-160-1.) and the Pulse-Echo method (PEM) for quick pile integrity test on a site with a large number of piles (ASTM D5882).